|

Model |

Speed |

Flow |

Head |

Shaft Power |

Efficiency |

Matching Motor |

Max Particle size

|

|

r/min |

m³/h |

m |

kw |

% |

mm |

||

|

150TLY-35 |

980 |

198 |

17.9 |

15.3 |

63.1 |

Y225M-6/V1 380V/30KW |

15 |

|

332 |

13.2 |

17.5 |

68.1 |

||||

|

364 |

12.1 |

18 |

66.8 |

||||

|

730 |

147 |

10 |

6.3 |

63.1 |

Y180L-8/V1 380V/11KW |

||

|

247 |

7.3 |

7.2 |

68.1 |

||||

|

271 |

6.7 |

7.4 |

66.8 |

||||

|

590 |

119 |

6.5 |

3.3 |

63.1 |

Y160L-6/B3 380V/11KW |

||

|

200 |

4.8 |

3.8 |

68.1 |

||||

|

219 |

4.4 |

3.9 |

66.8 |

||||

|

100TLY-34 |

1480 |

157 |

36.8 |

26.1 |

60.2 |

Y225M-4/V1 380V/45KW |

14 |

|

214 |

32.6 |

29.2 |

65.1 |

||||

|

293 |

24.4 |

33.5 |

58.2 |

||||

|

970 |

103 |

15.8 |

7.4 |

60.2 |

Y180L-6/V1 380V/15KW |

||

|

140 |

14 |

8.2 |

65.1 |

||||

|

192 |

10.5 |

9.4 |

58.2 |

||||

|

80TLY-45 |

1490 |

125 |

81.6 |

53.3 |

52.2 |

Y315S-4/V1 380V/110KW |

15 |

|

237 |

66.8 |

73.8 |

58.5 |

||||

|

286 |

56.7 |

84.1 |

52.6 |

||||

|

980 |

82 |

35.3 |

15.1 |

52.2 |

Y112M-4/B5 380V/37KW |

||

|

156 |

28.9 |

21 |

58.5 |

||||

|

188 |

24.5 |

23.9 |

52.6 |

||||

|

ReviewsThere are no reviews yet. This site is registered on wpml.org as a development site. Switch to a production site key to remove this banner. |

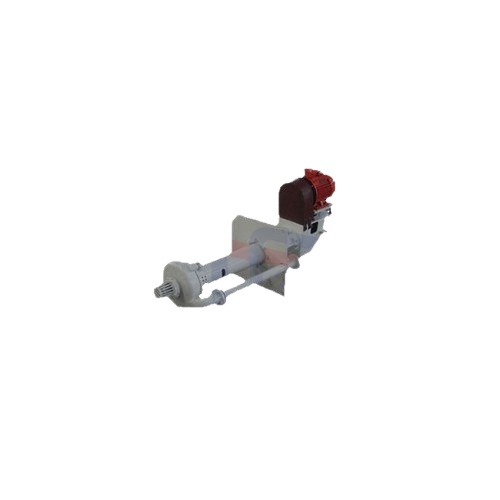

TLY Series Desulfurization Pump

-

The TLY series desulfurization pump developed and produced by our company is of axial suction, single stage single suction, bracket (suspension) centrifugal structure. This series of pumps combines the advantages of similar products at home and abroad and makes innovations in hydraulic design, structural design and casting materials. It has the characteristics of high efficiency, energy saving, corrosion resistance, low vibration, low noise, reliable operation, long service life and convenient maintenance. It can be widely used in the desulphurization system of thermal power generation, aluminum smelting and oil refining industries to transport lime or gypsum slurry. The maximum allowable slurry weight concentration CW is 60%, the maximum chloride ion content is 60000ppm, the PH value is 2.5-13, and the slurry temperature is ≤65℃.

The pump adopts a single pump casing vertical structure, and the flow parts are made of corrosion-resistant and wear-resistant chromium-nickel alloy; the shaft seal adopts a non-flushing water mechanical seal form to prevent pump fluid leakage and avoid damage to the bearing.

Reviews

There are no reviews yet.