|

Flange type |

Welding Holland International Group neck |

|

Materials |

ASTM A105; A350 LF2; A694 F42,F46,F52,F56,A182 F12 / F22 / F5 / F9 / |

|

Size |

1/2“~60”,As a customer’s request; |

|

Pressure |

Classification:150 300 400 600 900 1500 |

|

Standard |

ASME B16.5,ASME B16.47,MSS SP43,EN1092 ,DIN,JIS; |

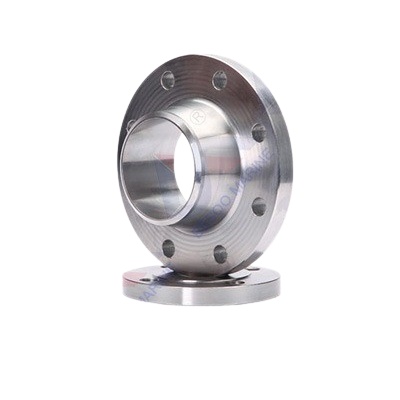

Welded Neck Flange

-

Nail Welded neck flange (also known as high hub flange and conical hub flange) ) Is a flange.

Welded neck flanges are easily recognizable at long conical wheels, gradually turning from pipes or fittings to wall thicknesses. There are two types of designs. General types are used with pipes. Long type is not suitable for piping, used in processing plants. The welded neck flange consists of a circular accessory with a protruding edge around it. Usually through forging processing, these flanges are usually welded to the pipe.

There is a series of boreholes on the rims that allow flanges to be bolted to another flange. This flange is suitable for harsh environments with extreme temperature, pressure or other stress sources. The elasticity of this type of flange is achieved by sharing the environmental stress with its welded pipes.

This type of flange has been successfully used for pressure up to 5,000 psi. These flanges are drilled to match the inner diameter of the mating tube or accessory and therefore do not limit the flow of the product. This prevents turbulence at the joints and reduces corrosion.

They also provide excellent stress distribution through conical wheels and can be flaw-detecting via radio graphics. Welded neck flanges will be welded to pipes or fittings with a single full penetration, V welding (butt welding).

نقد و بررسیها

هنوز بررسیای ثبت نشده است.

نقد و بررسیها

هنوز بررسیای ثبت نشده است.