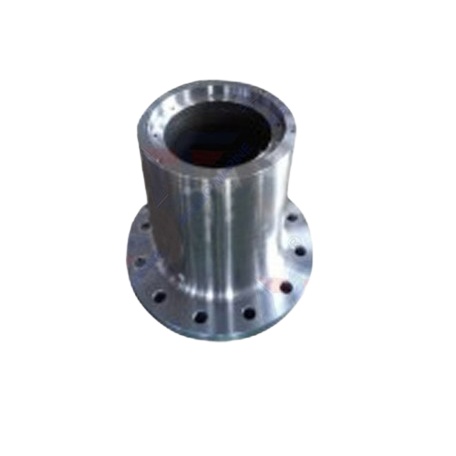

Hydraulic coupling

-

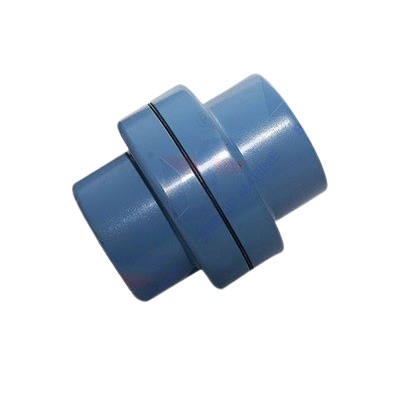

Coupling is used to connect the main propulsion shaft of a ship with the intermediate shaft, the output flange of the gearbox and the output flange of the main engine. Mainly by the inner sleeve, jacket, seal ring, piston, pressure ring, bolt, etc.

Working principle: use the same cone surface between inner and outer coat, inject hydraulic oil in the radial and axial direction of outer coat at the same time, make outer coat move up to the design value, then remove the radial and axial oil pressure, make outer coat press inner sleeve, inner sleeve press the shaft, transfer torque through the friction force between each other.

The advantages of hydraulic coupling are safety and reliability, convenient installation and disassembly, low maintenance cost, long service life.

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.